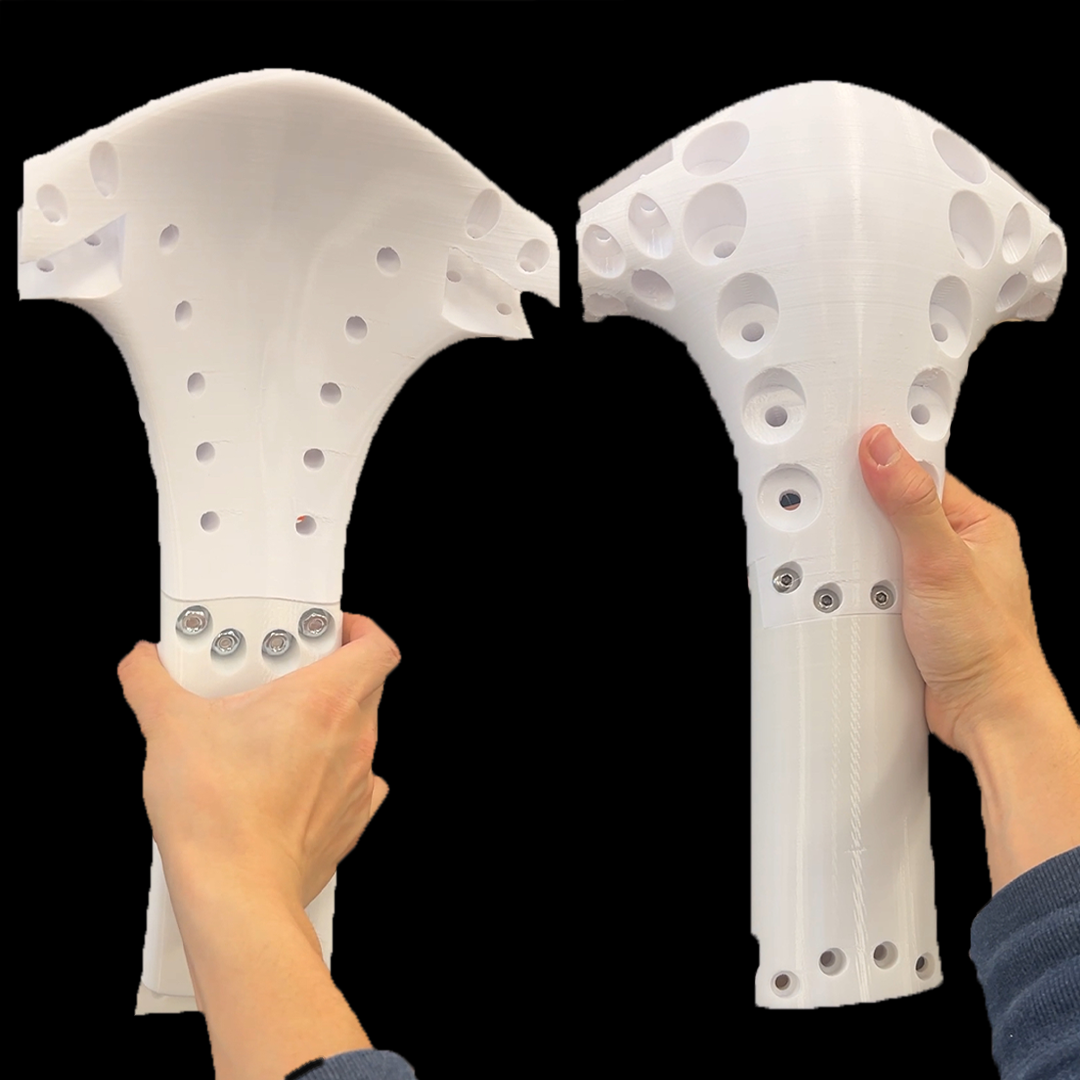

Final Photos

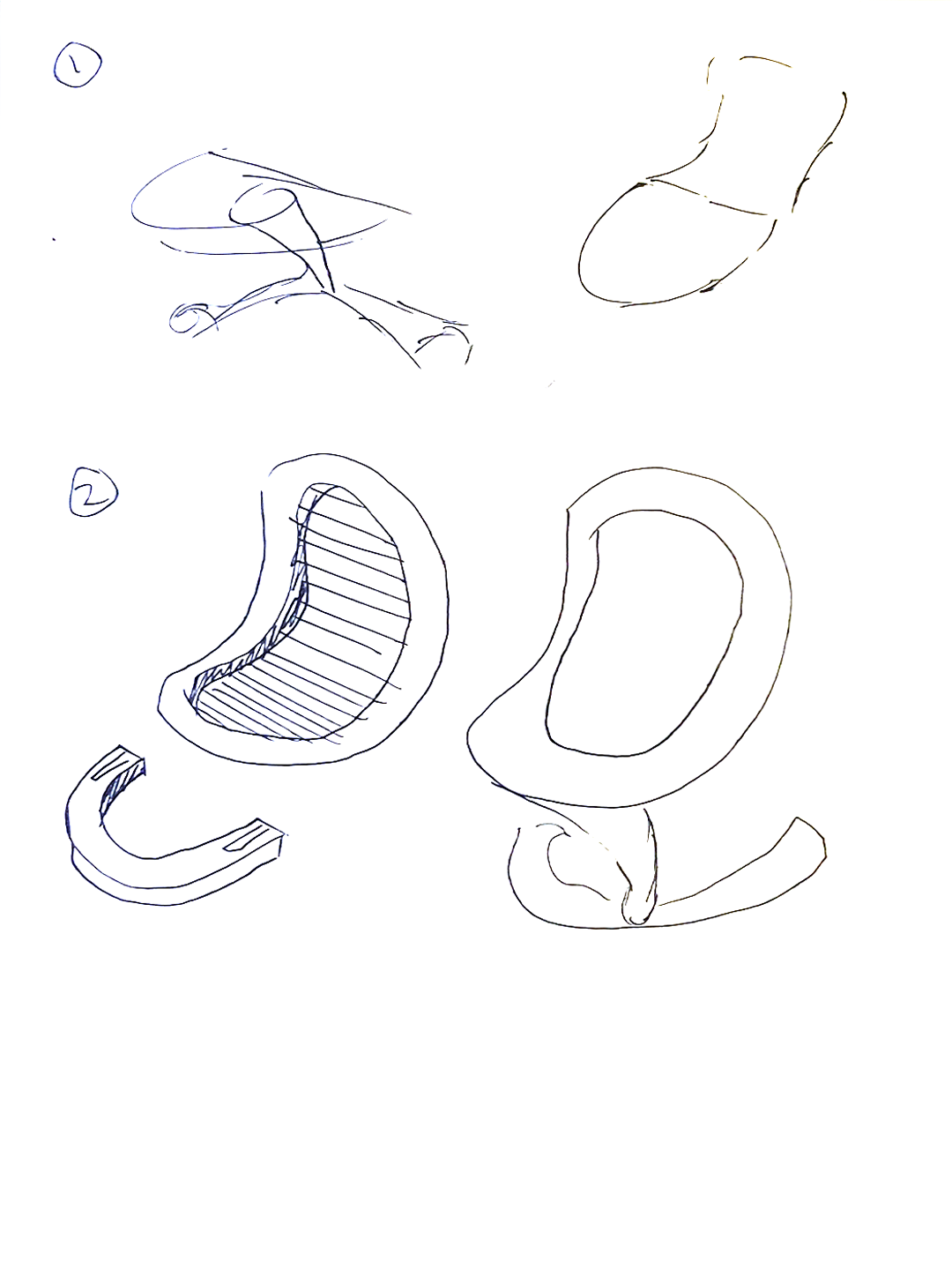

In traditional, contemporary, and experimental guitar building processes, the conflicting structural needs are ever present; A luthier must find a way to stabilize a cantilevering neck in tension from a number of strings running from a headstock to a body.

Guitars are ideally light enough to hold in performance and practice, but sturdy enough to meet these structural demands. Common strategies include embedding a truss rod into the neck, as well as dovetail and bolted connections from neck to body.

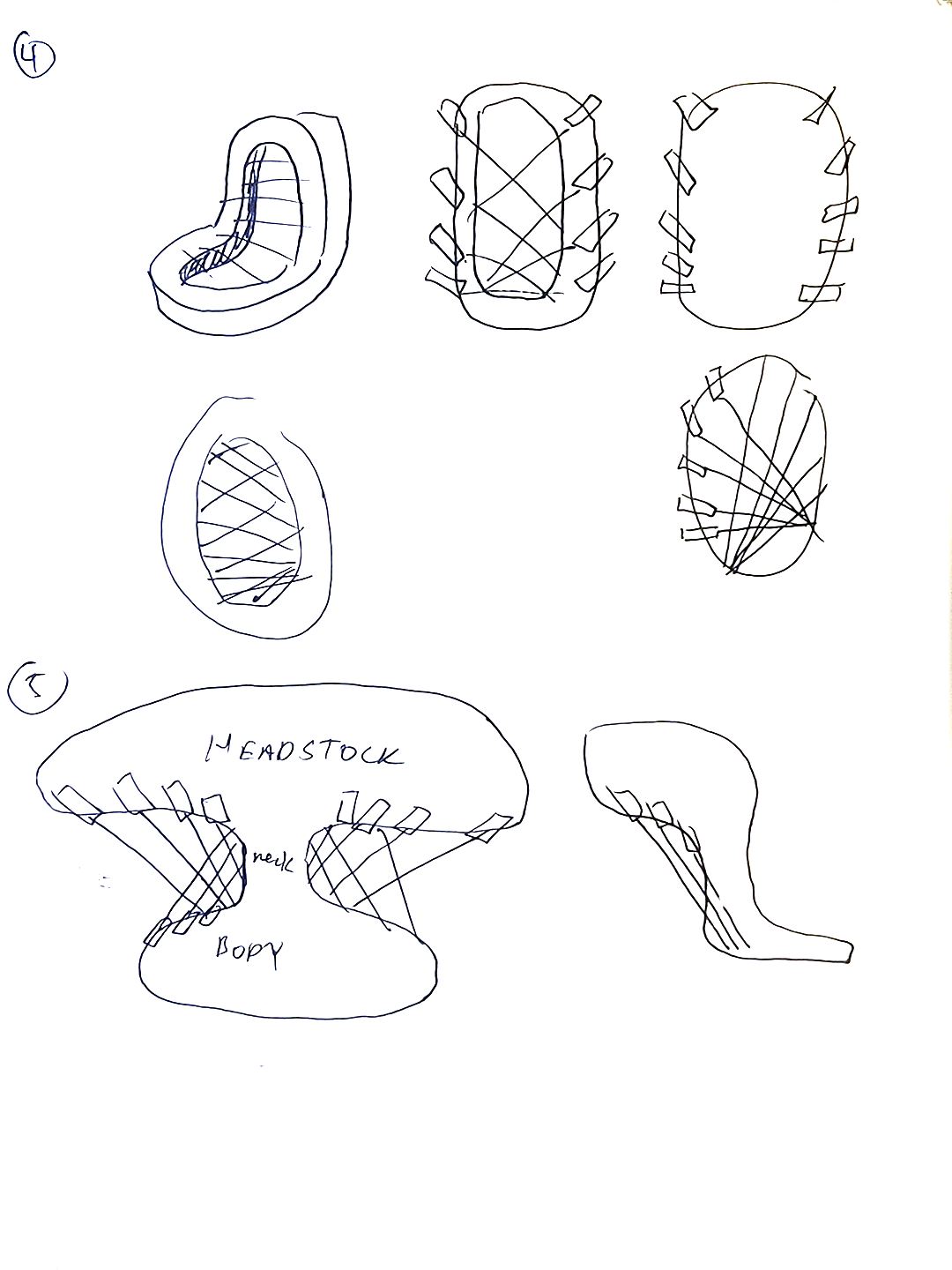

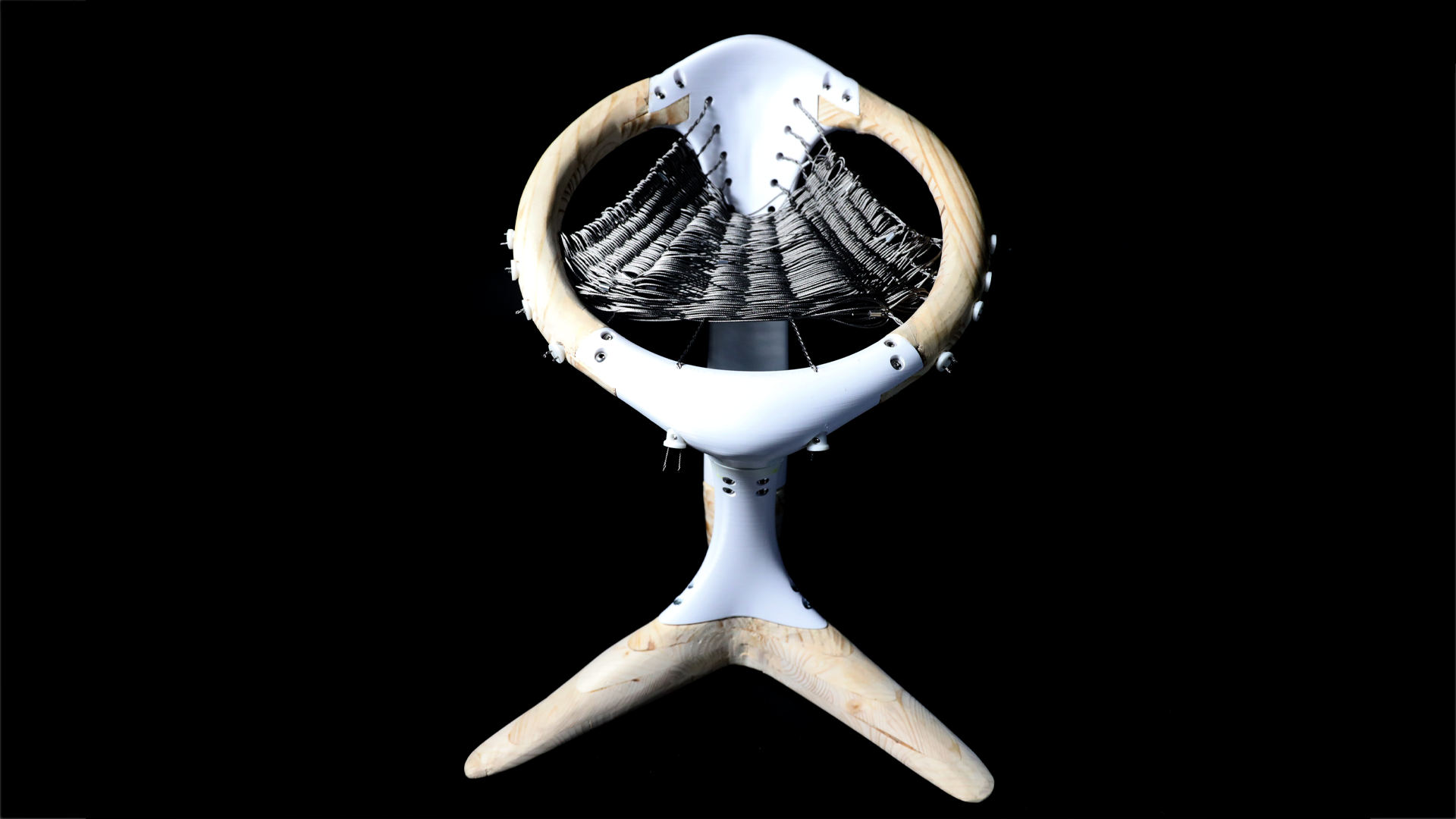

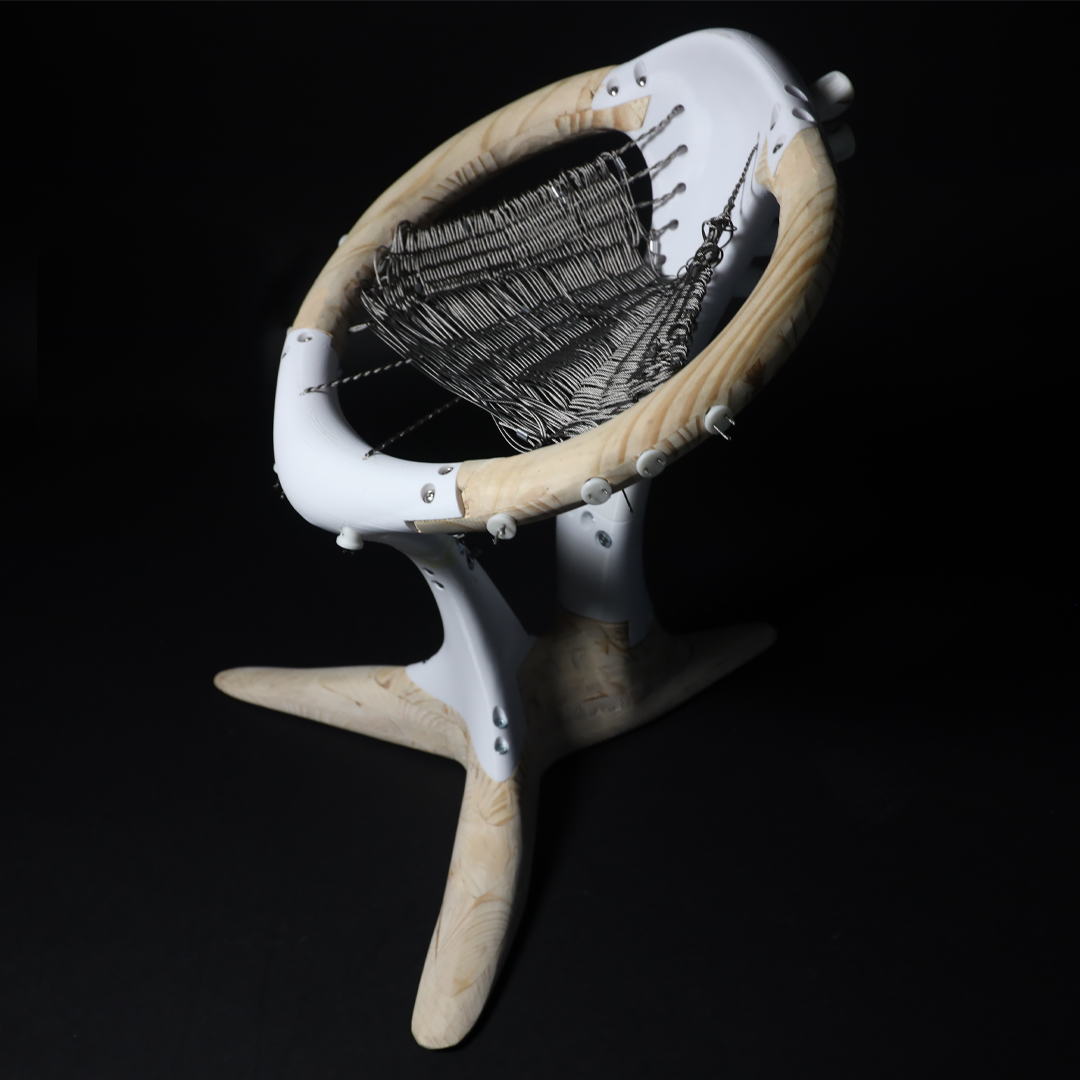

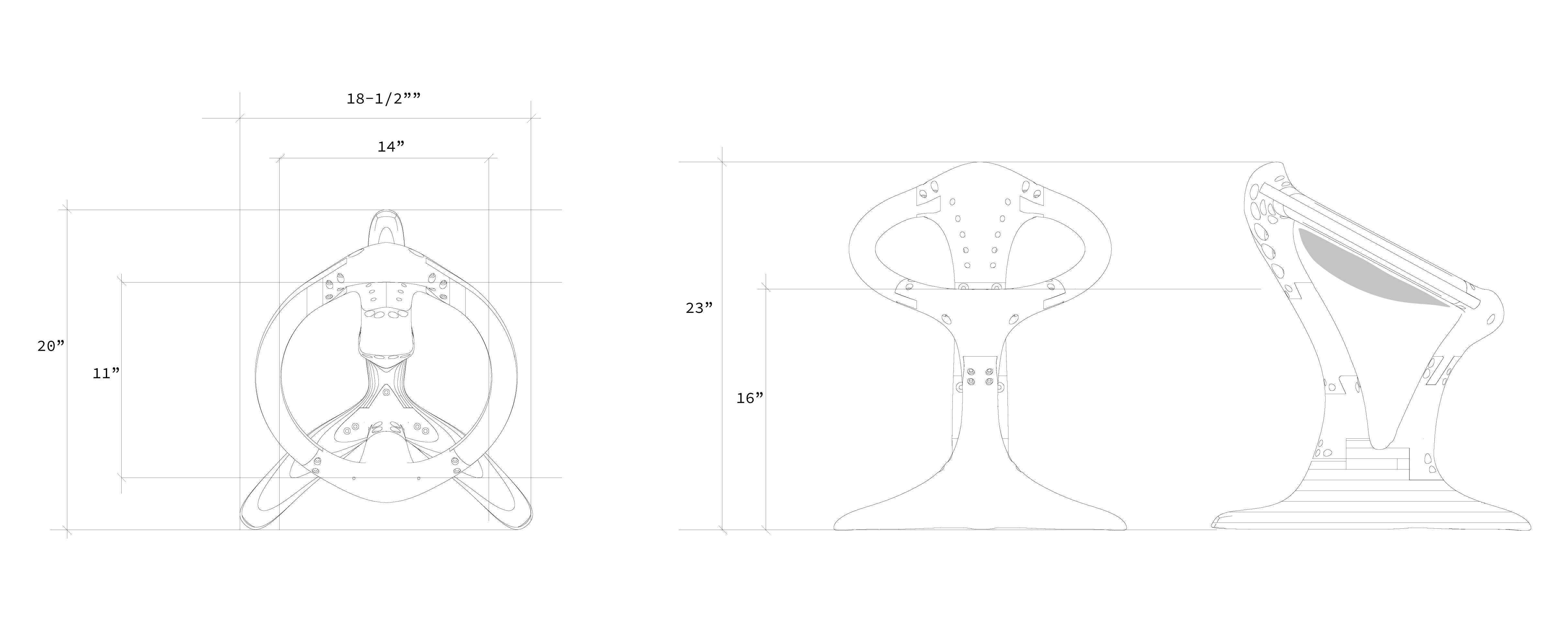

These building strategies--the ingredients for building most guitars--are transferred and translated into the design of a chair meant for practicing the instrument. Of particular importance was the balance between a light-looking frame and sturdiness, as well as the uneven loading condition which practicing the guitar presents.

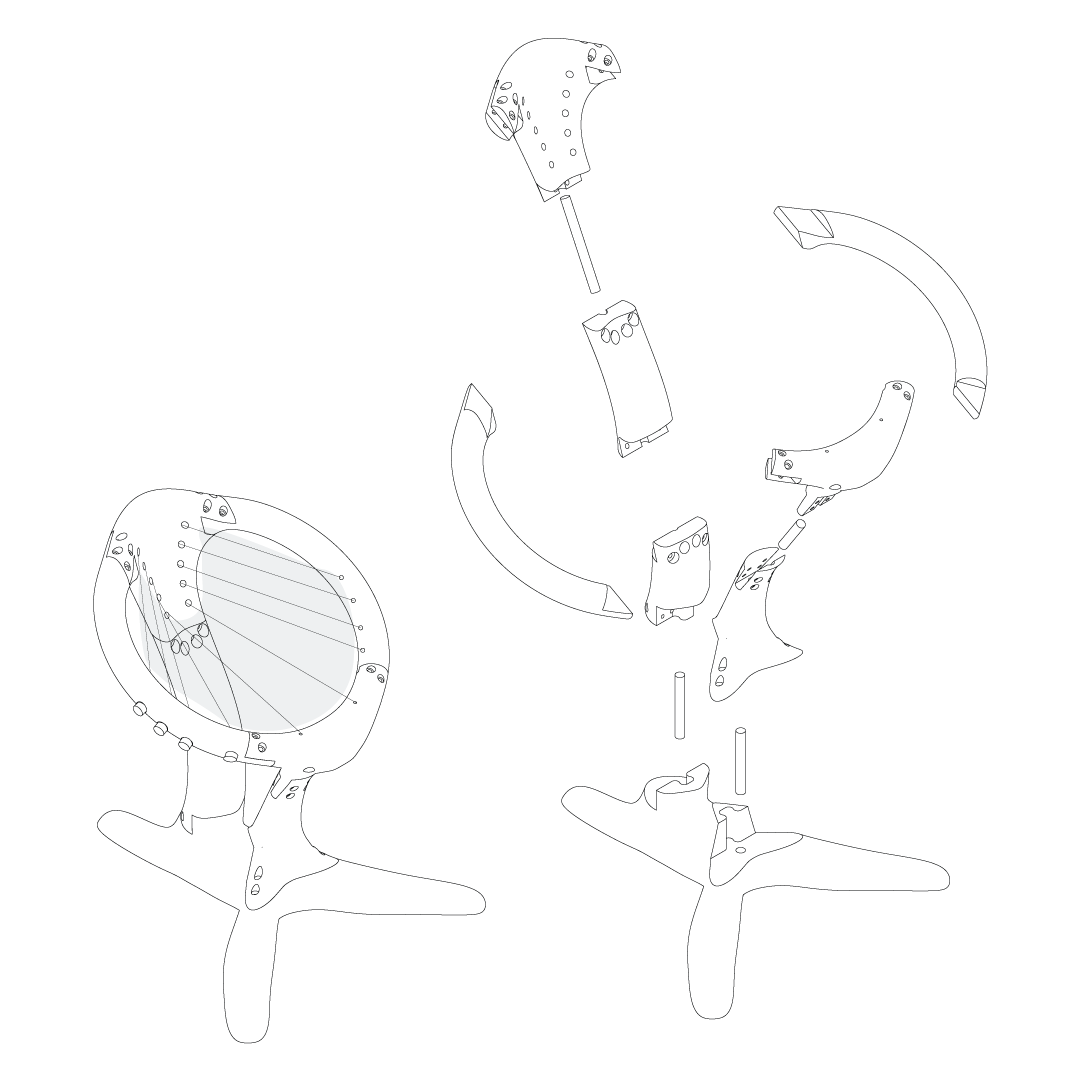

The final design allows for a degree of disassembly and the further customization of a core “body.” The tensioning system, in particular, encourages an attitude of care and maintenance of the chair in a way that is similar to that of a guitar.

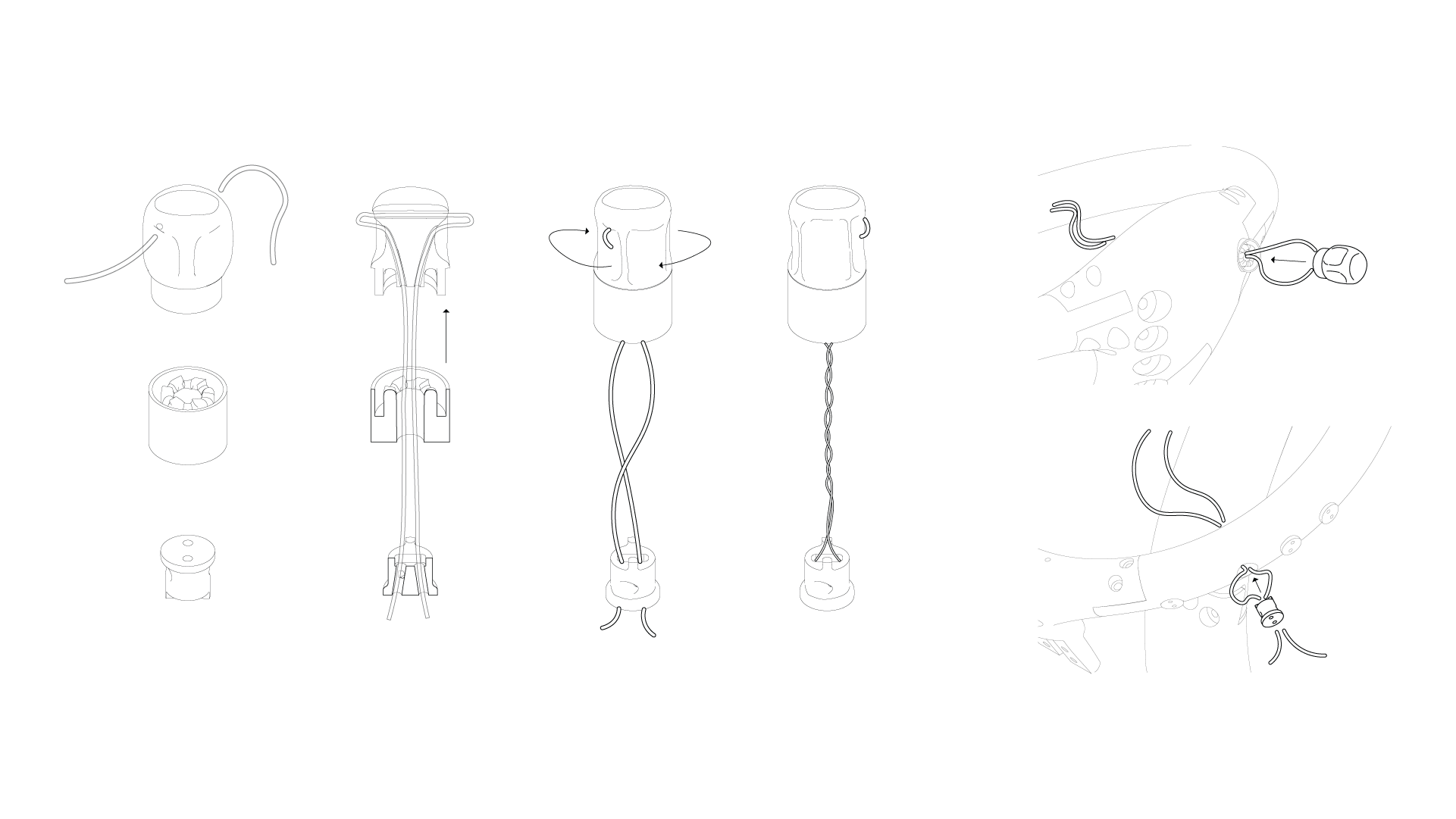

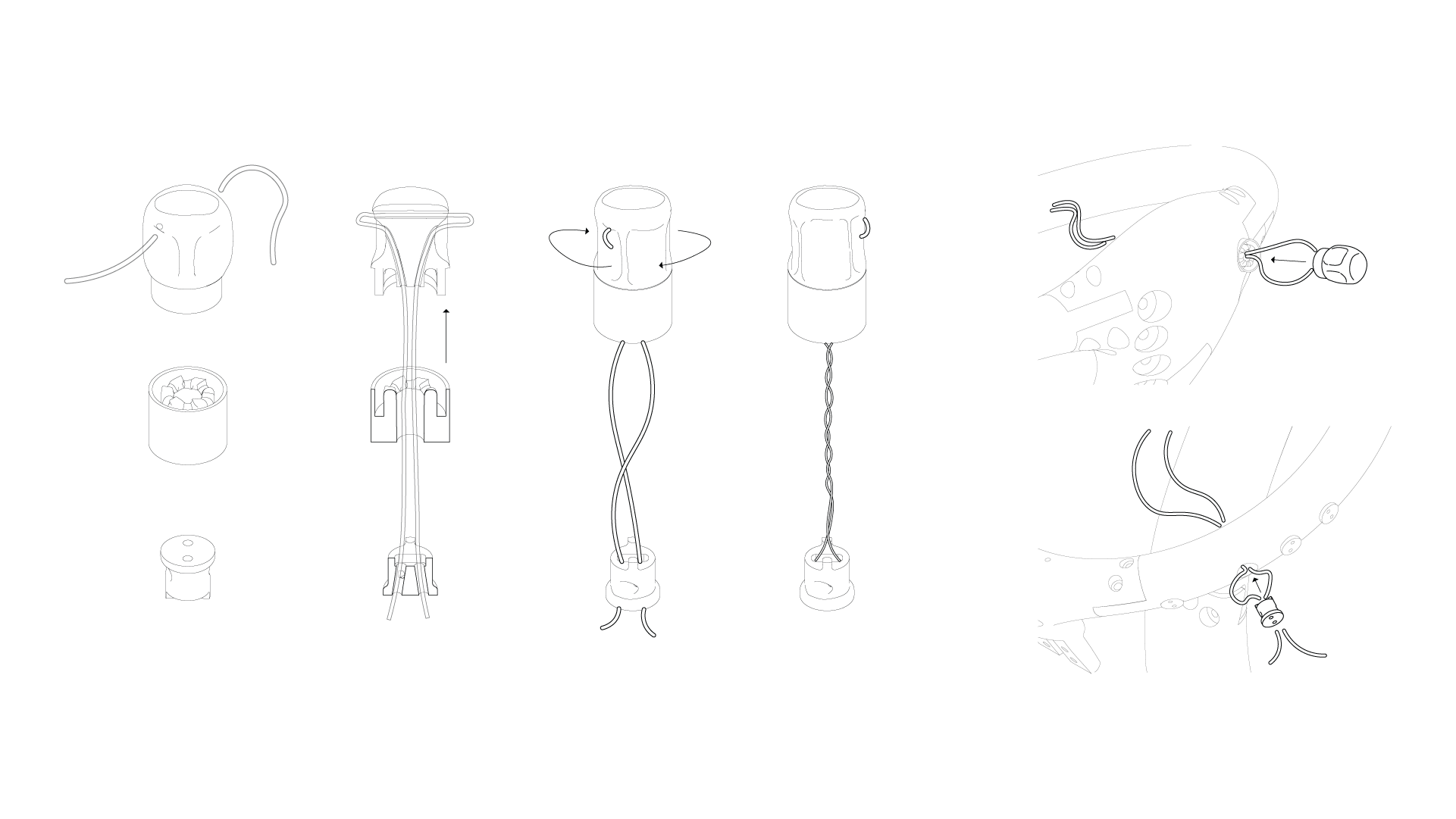

Tensioning System Demonstration

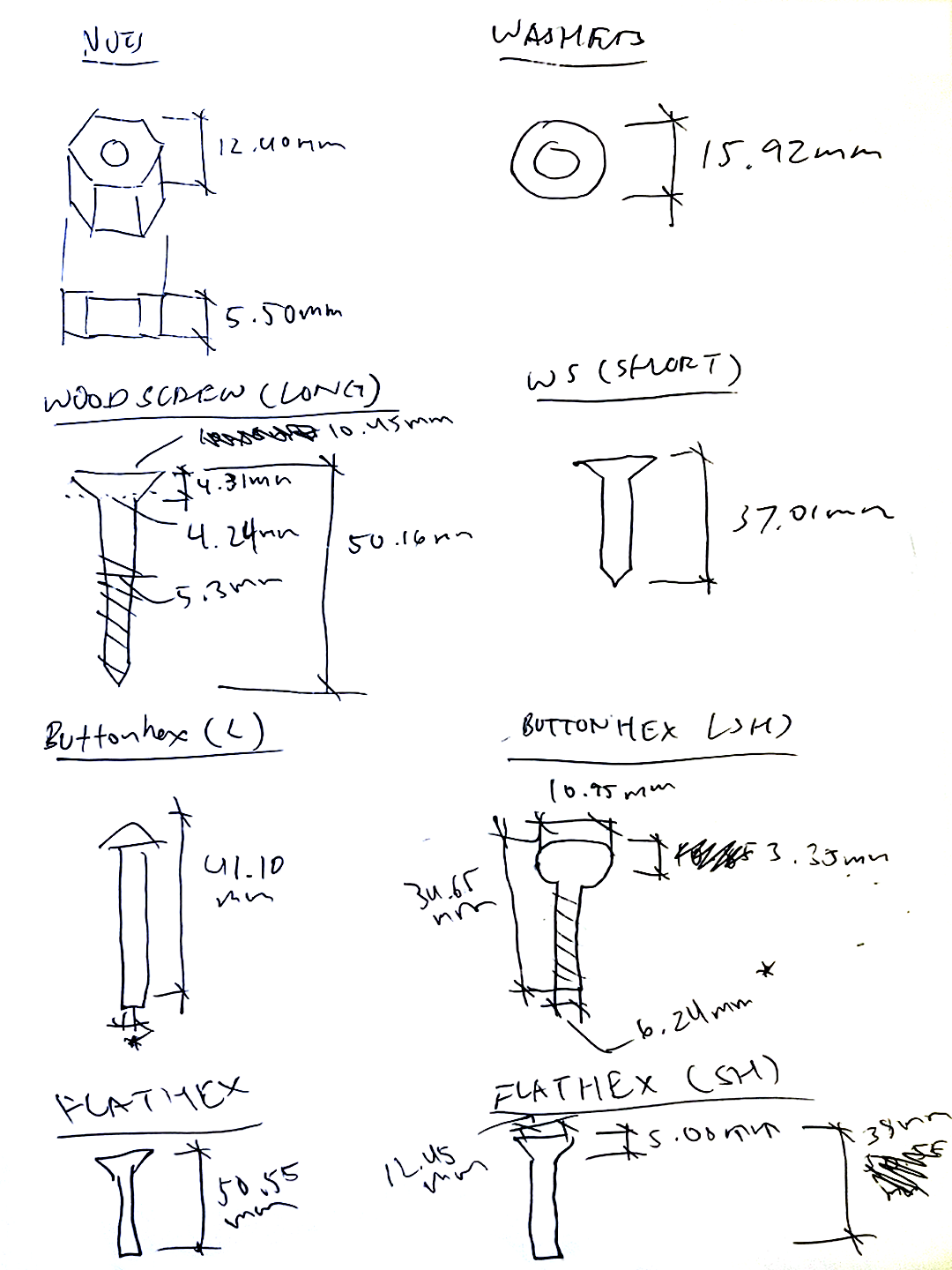

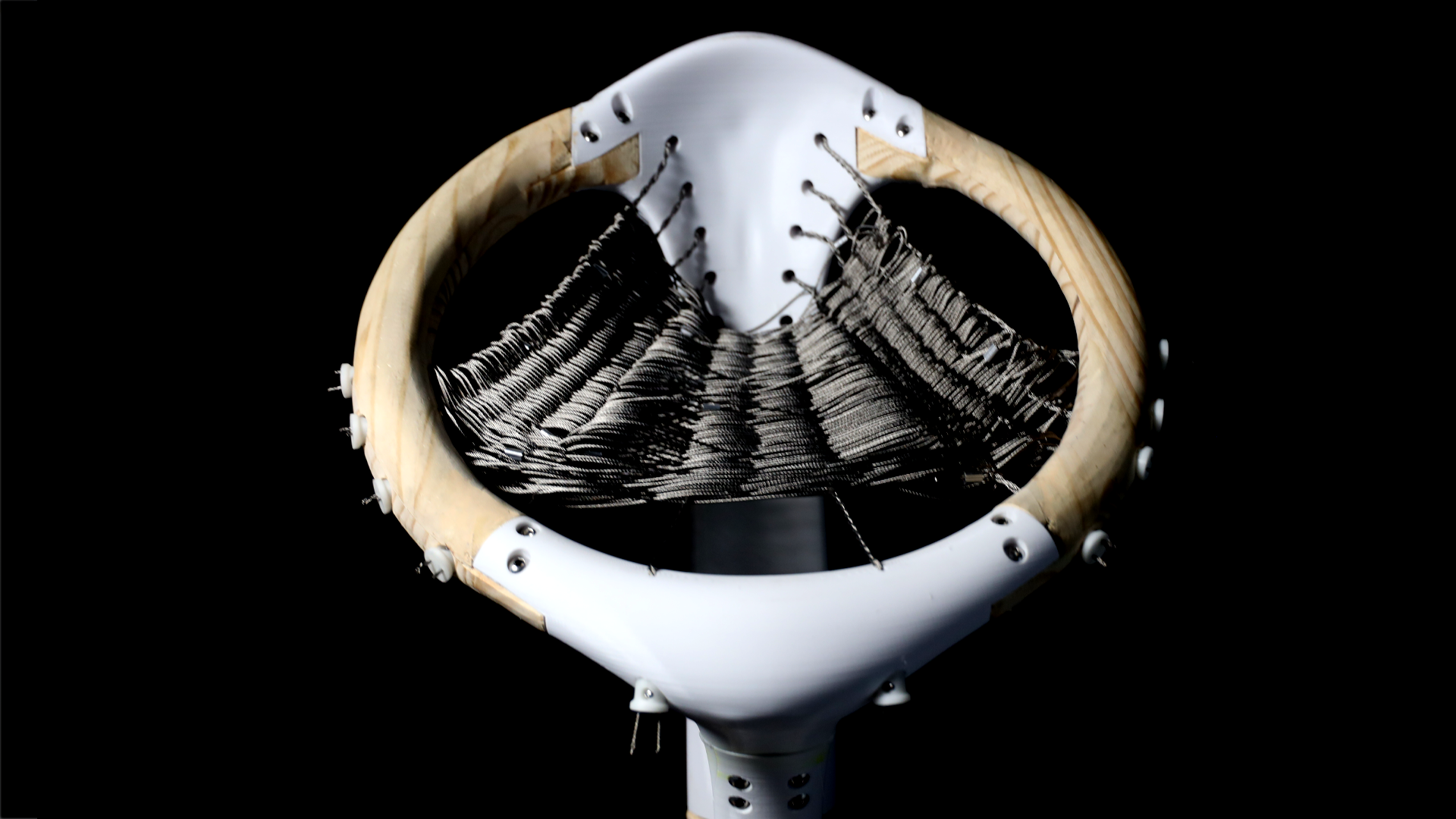

1/16" cables are wound together through tension knobs. The assembly (see below) takes cues from the string-through bodies

of electric guitars, in which tuning pegs tension guitar strings while metal ferrules stabilize them from the back of the body.

Unlike guitar tensioning systems, the chair relies on low-gauge (and much cheaper) steel cable as the loading condition changes from the system itself to both the system as well as an additional body and guitar. The twisting action is preserved while the knobs themselves take more after the strandberg bullet designs, and also winds the cable onto itself in a helical fashion.

Play the videos with your sound on! The hidden ridges both keep the knob-wire system from unfurling but also provide resistance that leads to a satisfying clicking noise with each turn.

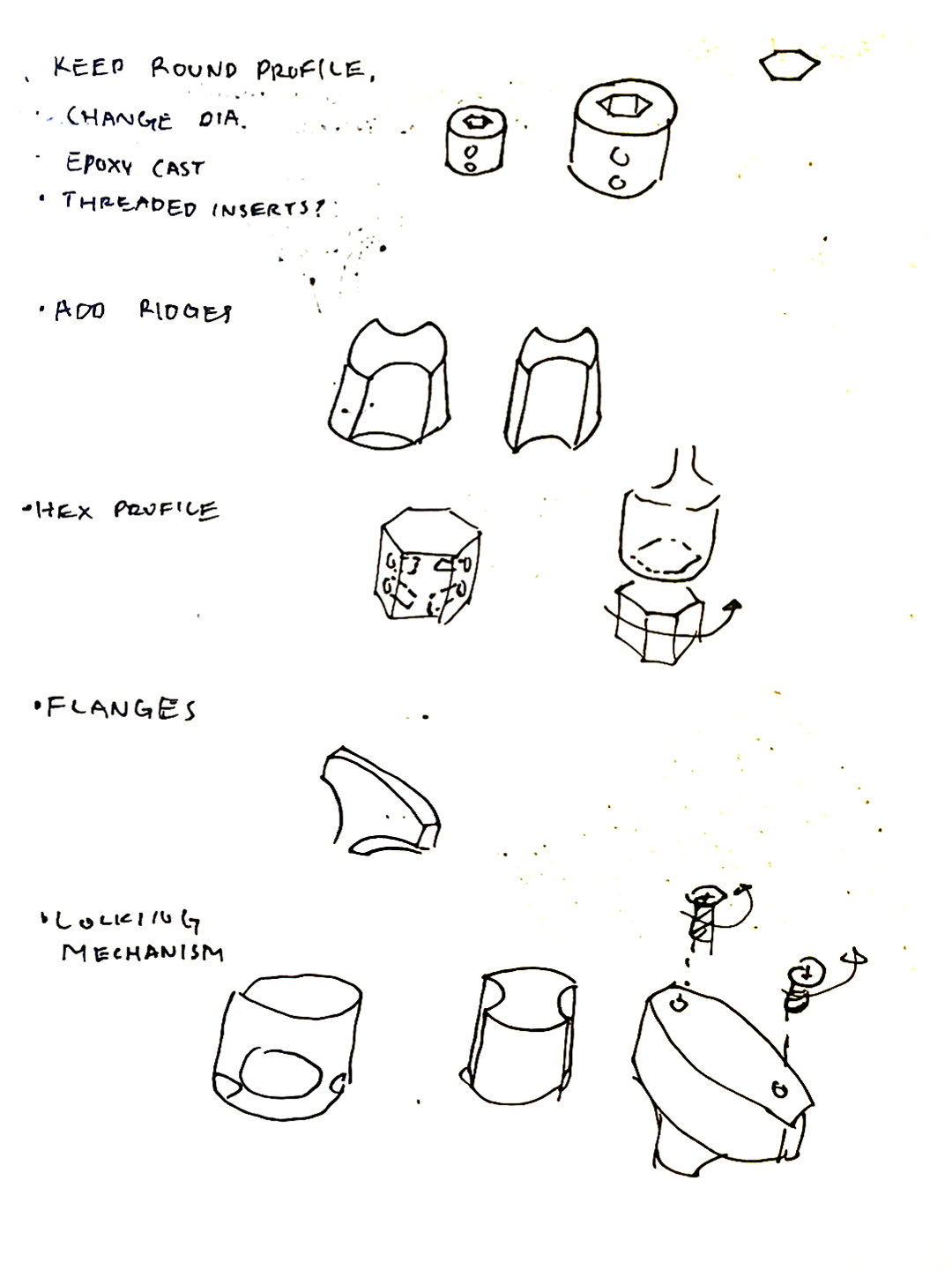

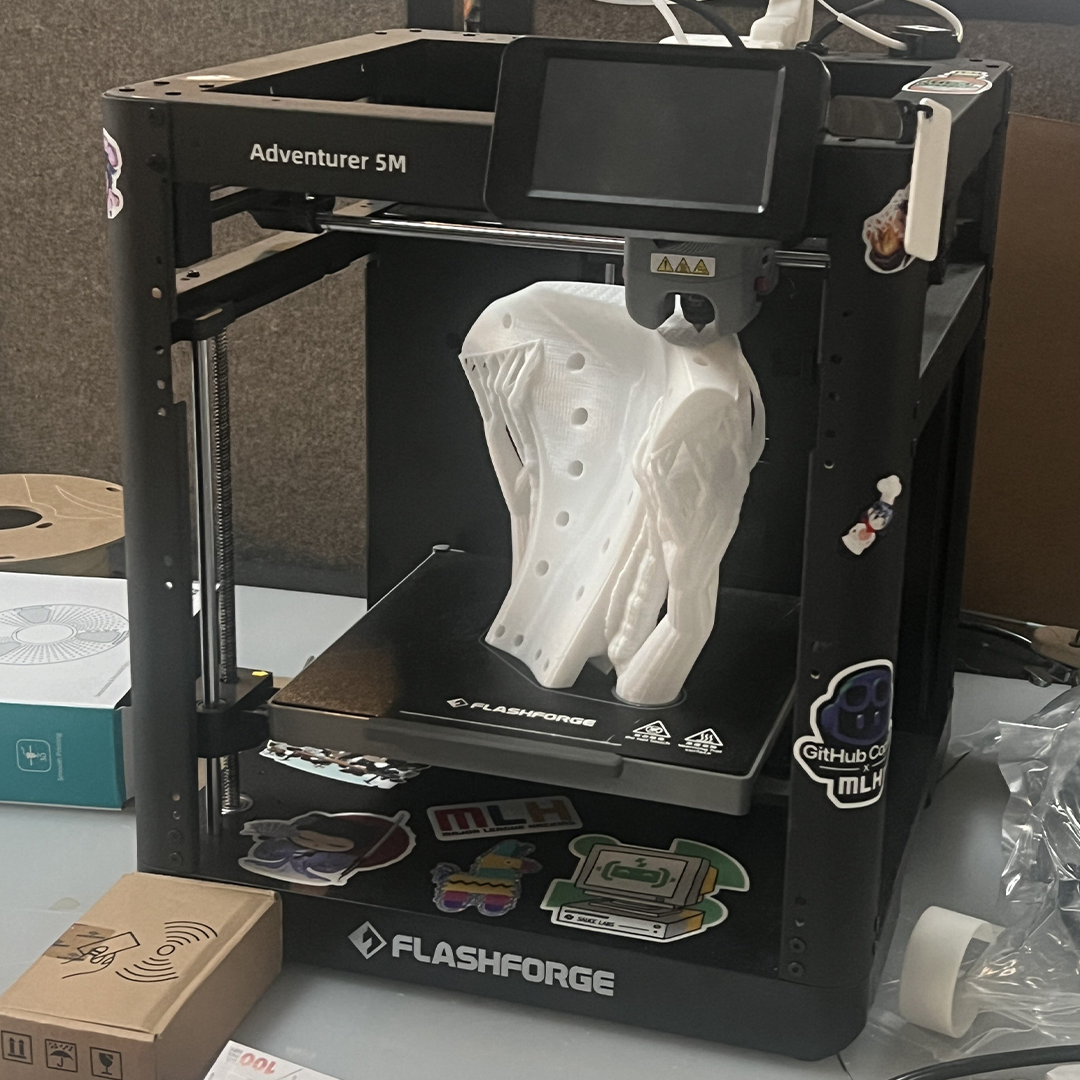

Prototypes

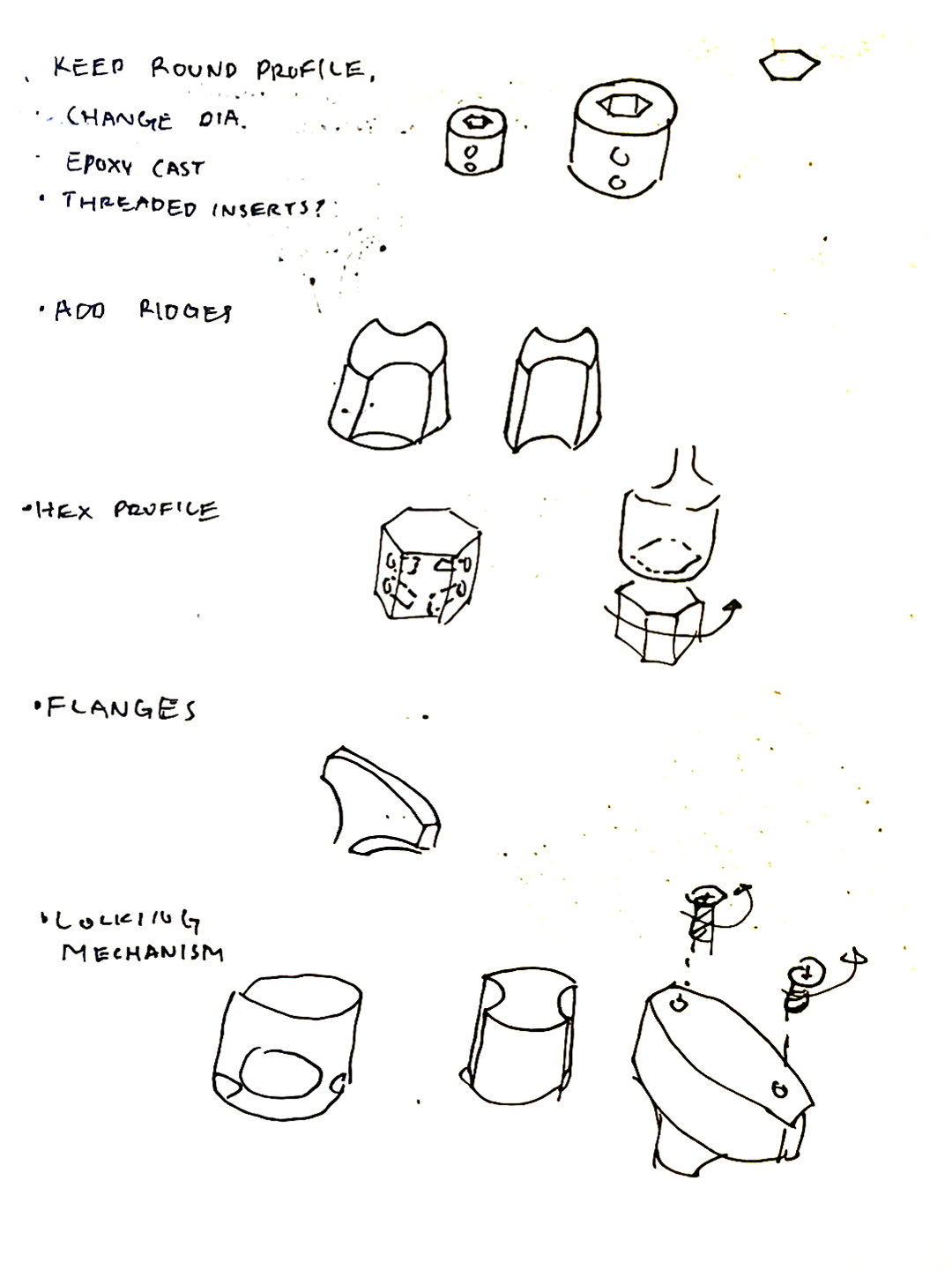

Throughout the semester, tensioning prototypes were created in parallel to the overall design development of the chair.

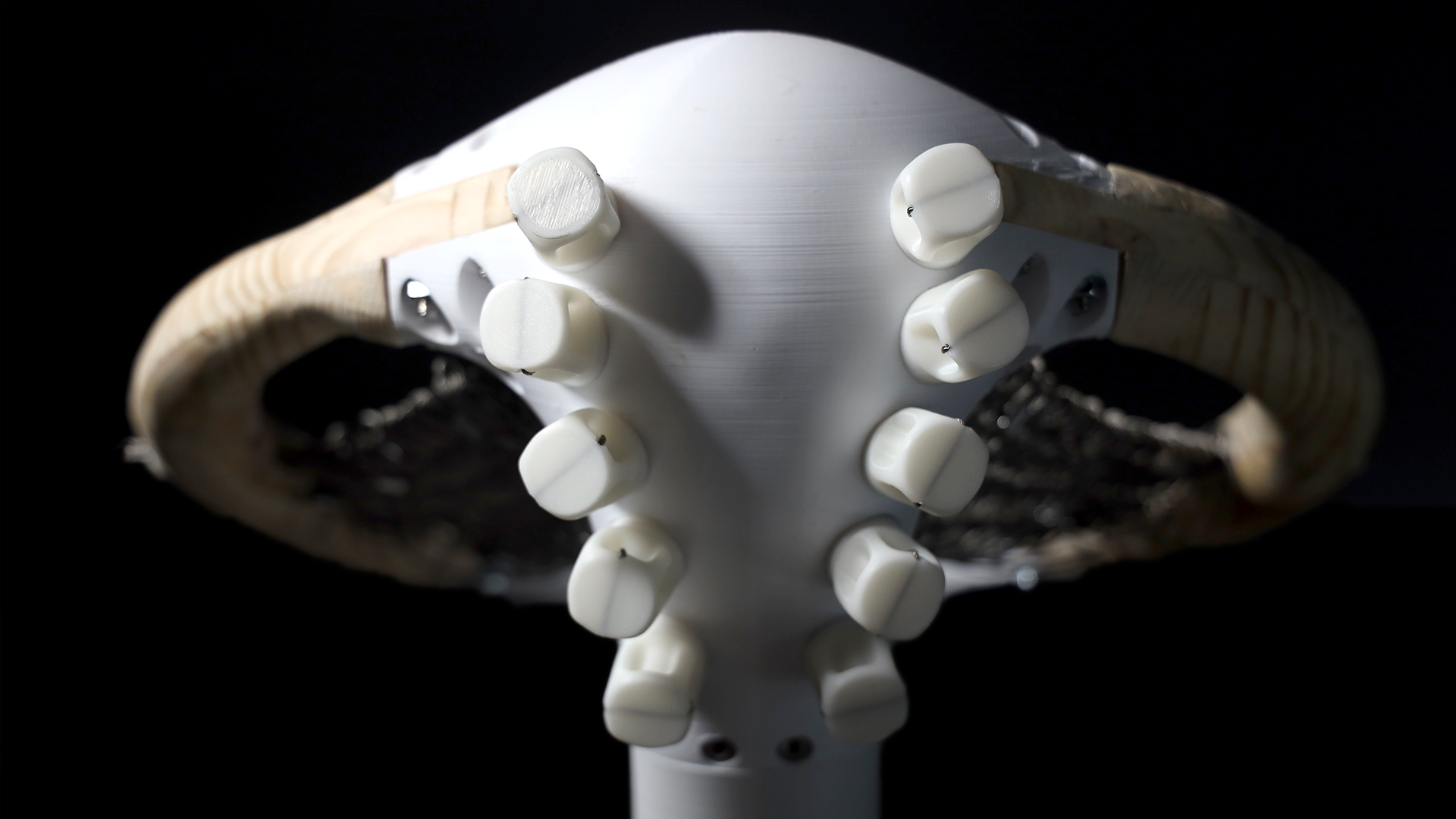

Knob sizes, textures such as knurling and hand-indentations, and overall connection details went through several iterations

before reaching the eventual bullet shape.

Below is an early prototype testing knurling and spanning; I determined that 3d printed knurls at this scale produced friction but were uncomfortable, leading me to the eventual indentation design so that the user would still be able to generate enough torque while having a good grip.

Sitting on The Chair

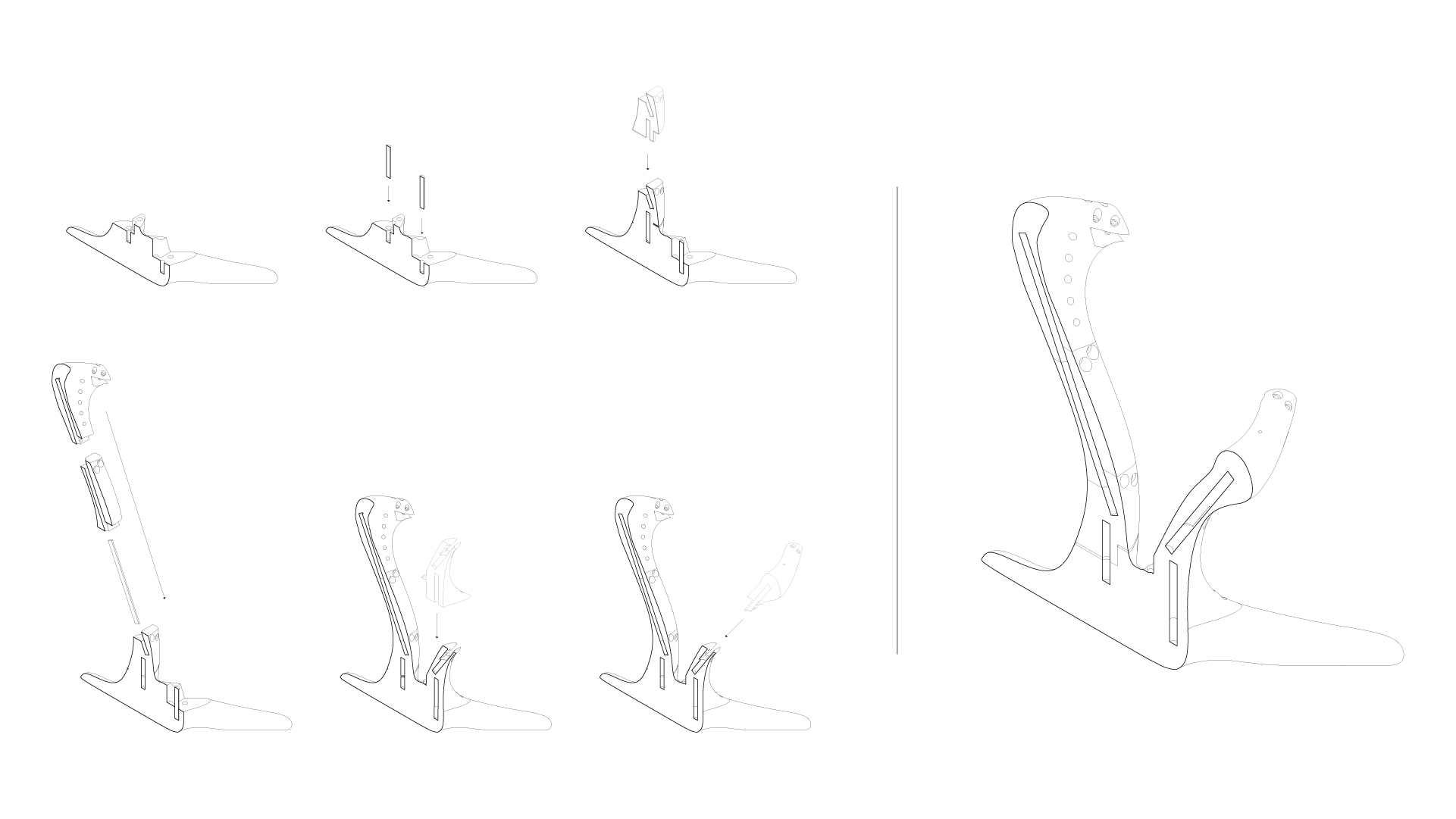

Assembly Diagrams

Process Photos

Sketches